OEM Non-Rising Stem Gate Valve: Key Features and Benefits for Industrial Applications

2025-12-30

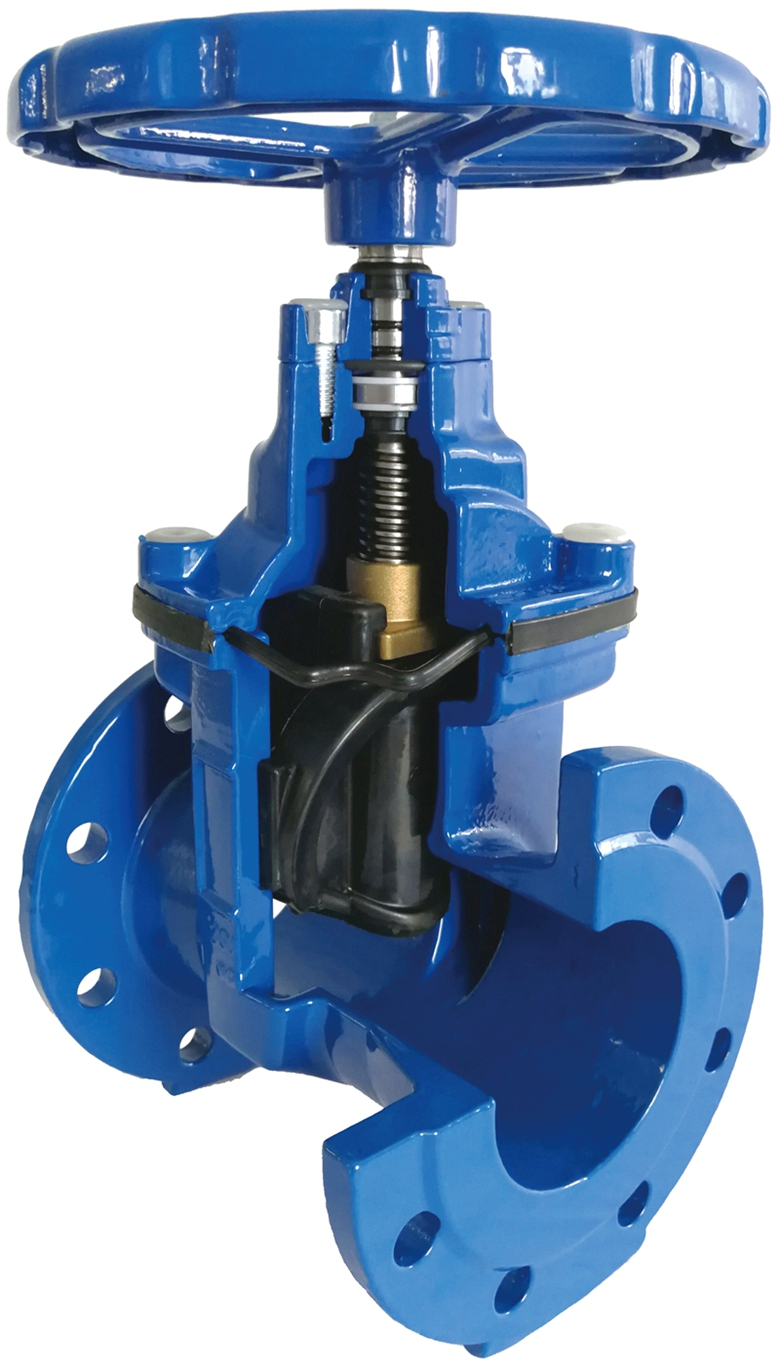

In today's fast-paced industrial landscape, optimizing operational efficiency and reliability is paramount. For engineers and procurement specialists, selecting the right valve can be the difference between seamless workflow and costly downtime. Enter the DRIFCO OEM Non-Rising Stem Gate Valve—a game-changer designed to tackle demanding applications with precision and durability. While gate valves are common, this specific variant offers unique advantages that set it apart, from space-saving design to enhanced sealing capabilities. This blog delves into the key features and benefits that make the DRIFCO Non-Rising Stem Gate Valve a standout choice for industries ranging from oil and gas to manufacturing. Ready to discover how it can elevate your systems? Let's explore what makes this valve a smart investment for any industrial setup.

Exploring the Durability and Longevity of OEM Non-Rising Stem Gate Valves in Harsh Environments

When it comes to OEM non-rising stem gate valves, their ability to withstand harsh environments often goes unnoticed until put to the test in real-world applications. These valves are engineered with robust materials like stainless steel or corrosion-resistant alloys, which help them resist extreme temperatures, high pressures, and aggressive chemicals. Unlike rising stem designs, the non-rising stem mechanism keeps the stem protected within the body, minimizing exposure to external elements that could lead to wear or failure. This inherent design feature significantly enhances their durability, making them a reliable choice for industries such as oil and gas, chemical processing, and wastewater treatment where conditions are notoriously unforgiving.

Longevity in these valves isn't just about material strength; it's also tied to meticulous manufacturing standards and regular maintenance. OEMs typically adhere to strict quality control processes, ensuring that each valve meets specifications for sealing, torque, and operational efficiency. In harsh settings, factors like abrasive particles or frequent thermal cycling can accelerate degradation, but proper installation and periodic inspections can extend service life. For instance, applying protective coatings or using compatible lubricants can prevent rust and reduce friction, allowing the valve to function smoothly over years of use without compromising performance.

Moreover, the longevity of non-rising stem gate valves in challenging environments is often validated through rigorous testing, including accelerated aging and pressure cycling simulations. This empirical data helps manufacturers refine designs, such as improving stem packing or enhancing body geometry, to better handle stress and corrosion. By focusing on these aspects, users can rely on these valves to maintain integrity and operability, even in settings that would quickly degrade less durable alternatives. This makes them a cost-effective solution in the long run, as reduced downtime and fewer replacements translate to lower overall operational costs.

How Non-Rising Stem Design Enhances Space Efficiency and Safety in Industrial Settings

In industrial environments where space is at a premium, every inch matters. Non-rising stem designs, often found in gate and globe valves, address this challenge by keeping the stem stationary during operation. Unlike rising stem valves that require vertical clearance for their stems to move up, non-rising models operate without protruding components. This design allows for installation in tight or congested areas, such as pipelines running close to ceilings or in compact machinery setups, maximizing usable space without compromising functionality.

Safety is a critical concern in sectors like chemical processing or oil refineries, and non-rising stem valves contribute significantly by reducing risks. Their fixed stems eliminate the potential for entanglement or snagging with personnel or equipment, especially in high-traffic zones. Moreover, the enclosed mechanism minimizes exposure to corrosive substances or extreme temperatures, lowering the chance of leaks and accidents. This inherent stability also ensures consistent, reliable valve operation, preventing sudden failures that could lead to hazardous incidents or costly downtime.

Beyond just saving space and enhancing safety, non-rising stem designs offer practical advantages that streamline industrial workflows. Their compact nature simplifies maintenance and inspection, as fewer moving parts are exposed, reducing wear and tear over time. This durability translates to longer service life and fewer replacements, cutting operational costs. By integrating these valves into systems, industries can achieve a more efficient, safer, and cost-effective infrastructure, making them a smart choice for modern applications demanding precision and resilience in constrained settings.

Key Material Innovations in OEM Gate Valves for Superior Corrosion Resistance

In the world of industrial fluid control, the durability of gate valves often hinges on how well they withstand harsh environments, especially those involving corrosive media. One standout advancement has been the integration of specialized alloys like super duplex stainless steels, which blend high chromium and molybdenum content with nitrogen additions to create a robust barrier against pitting and crevice corrosion. This isn't just about throwing more metal at the problem; it's a precise chemical tweak that allows these valves to thrive in offshore oil rigs or chemical plants where saltwater and acids would quickly degrade standard materials. By focusing on such tailored compositions, manufacturers have pushed beyond generic solutions, delivering components that not only last longer but also reduce maintenance headaches in critical applications.

Beyond traditional metals, the adoption of engineered polymers and composite materials has opened new frontiers in corrosion resistance. Take, for instance, PTFE-lined gate valves or those reinforced with carbon fiber—these innovations leverage non-metallic elements to sidestep electrochemical degradation entirely. What sets them apart is their ability to handle aggressive fluids like chlorine or sulfuric acid without succumbing to rust or stress cracking, a common pitfall with conventional designs. This shift towards composites isn't just a material swap; it reflects a deeper rethink of valve architecture, prioritizing weight reduction and thermal stability to outperform in sectors like pharmaceuticals or wastewater treatment where purity and reliability are non-negotiable.

Another game-changer lies in surface treatment technologies, such as advanced coatings like HVOF-applied tungsten carbide or plasma-sprayed ceramics. These aren't mere protective layers; they're engineered shields that fuse with the valve body to create a seamless, impervious surface against corrosive attack. By enhancing hardness and wear resistance, these treatments allow gate valves to endure abrasive slurries or high-temperature steam without losing their sealing integrity. This approach moves beyond bulk material changes, offering a cost-effective way to upgrade existing valve lines for superior performance in demanding settings like mining or power generation, where every component must battle both corrosion and mechanical stress.

Streamlining Maintenance and Operational Ease with Advanced Valve Features

When it comes to keeping your systems running smoothly, advanced valve features are true game-changers. Imagine valves that not only control flow with precision but also come equipped with smart diagnostics that alert you before issues turn into costly breakdowns. With self-monitoring capabilities and predictive maintenance tools, operators can shift from reactive fixes to proactive upkeep, slashing downtime and boosting overall efficiency. It’s like having a built-in assistant that whispers when it’s time for a tune-up.

Operational ease goes hand-in-hand with these innovations. Think about user-friendly interfaces that allow quick adjustments with minimal training, or automated systems that handle complex tasks effortlessly. Features like intuitive controls and remote accessibility mean less fumbling and more focus on critical operations. This transforms valve management from a chore into a seamless part of daily workflows, making it accessible even for those without deep technical know-how.

Beyond the basics, these advancements open doors to customized solutions tailored to specific needs. From modular designs that simplify upgrades to energy-efficient models that reduce operational costs, they offer versatility that sets them apart. By embracing these cutting-edge features, facilities can not only streamline maintenance but also adapt to evolving demands, ensuring long-term reliability without the usual headaches.

Cost-Effectiveness and Energy Savings Through Efficient Flow Control Mechanisms

In industrial and commercial settings, efficient flow control mechanisms are more than just technical upgrades—they're financial game-changers. By optimizing how fluids like water, air, or chemicals move through systems, these mechanisms reduce energy consumption significantly. For instance, a well-designed valve or pump can cut power usage by up to 30%, translating into lower utility bills and a smaller carbon footprint. This isn't just about saving pennies; it's about building resilient operations that thrive in an eco-conscious market.

What sets modern flow control apart is its smart adaptability. Instead of relying on static, one-size-fits-all solutions, advanced systems use sensors and automation to adjust flow rates in real-time. Imagine a heating system that tweaks pressure based on occupancy or a manufacturing line that fine-tunes coolant flow to match production demands. This dynamic approach prevents energy waste during idle periods, boosting cost savings without compromising performance. It's a subtle shift that delivers outsized returns over time.

Beyond immediate savings, these mechanisms enhance long-term value by reducing wear and tear on equipment. Smooth, controlled flow means fewer pressure surges and less mechanical stress, extending the lifespan of pipes, pumps, and other components. Companies often overlook this aspect, but it's where the real payoff lies: fewer repairs, lower maintenance costs, and sustained efficiency. In a world where sustainability drives decisions, investing in efficient flow control isn't just practical—it's a strategic move that pays dividends for years to come.

Real-World Applications and Performance Benefits Across Diverse Industrial Sectors

Real-world applications of advanced technologies are transforming industries by delivering tangible performance benefits that go beyond mere efficiency gains. In manufacturing, for instance, the integration of IoT sensors and AI-driven analytics allows companies to predict equipment failures before they occur, drastically reducing downtime and maintenance costs. This proactive approach not only enhances production schedules but also improves product quality, as consistent monitoring ensures machines operate within optimal parameters. The result is a more resilient and competitive industrial landscape, where businesses can adapt quickly to market demands while minimizing operational risks.

Across diverse sectors such as energy, healthcare, and logistics, similar innovations are driving significant performance improvements. In the energy sector, smart grids powered by real-time data analysis enable better management of resources, leading to reduced waste and lower carbon emissions. Healthcare facilities leverage telemedicine and automated diagnostics to streamline patient care, increasing accessibility and accuracy in treatments. Logistics companies, on the other hand, use advanced routing algorithms and autonomous vehicles to optimize delivery routes, cutting down on fuel consumption and enhancing delivery speeds. These applications showcase how tailored solutions can address specific industry challenges, fostering growth and innovation.

The overarching performance benefits span from cost savings and increased productivity to enhanced safety and environmental sustainability. By adopting these technologies, organizations not only boost their bottom lines but also contribute to broader societal goals, such as reducing environmental impact and improving public health. For example, in agriculture, precision farming techniques that utilize drones and satellite imagery help farmers maximize crop yields with minimal resource use, promoting food security and sustainable practices. This holistic approach underscores the transformative power of technology across industrial sectors, creating a ripple effect of positive outcomes for businesses and communities alike.

FAQ

The primary advantage of an OEM non-rising stem gate valve is its compact design, which saves valuable space in crowded industrial installations, making it ideal for applications with height restrictions or limited room.

By keeping the stem stationary external to the valve, the non-rising stem design reduces the risk of injury from moving parts, enhancing safety in environments where valves are frequently operated or located near personnel.

These valves often use robust materials like stainless steel or corrosion-resistant alloys to withstand high pressures, abrasive fluids, and extreme temperatures, ensuring long-term durability and reduced maintenance needs.

They provide a tight seal when closed, preventing leaks and minimizing pressure drops, which helps maintain consistent flow rates and reduces energy waste in industrial fluid-handling systems.

Yes, OEM versions are designed for customization, allowing for tailored sizes, pressure ratings, and end connections to meet exact requirements in sectors like oil and gas, water treatment, or chemical processing.

The non-rising stem design reduces wear on external components and simplifies lubrication, leading to lower maintenance frequency and costs over the valve's lifespan without compromising performance.

They are engineered with reinforced bodies and precision-machined seats to manage high-pressure surges, ensuring reliable shut-off and control even under demanding conditions without stem damage or failure.

By offering precise fluid regulation and quick actuation, they support accurate process adjustments, helping industries optimize production flow and minimize downtime in critical operations.

Conclusion

OEM non-rising stem gate valves are engineered to offer exceptional durability and longevity, particularly in harsh industrial environments where exposure to corrosive elements, high pressures, and extreme temperatures is common. Innovations in materials, such as specialized alloys and advanced coatings, significantly enhance corrosion resistance, ensuring these valves withstand demanding conditions without compromising performance. This robust design not only minimizes downtime but also contributes to long-term reliability, making them a preferred choice for sectors like chemical processing, oil and gas, and water treatment. The non-rising stem mechanism plays a crucial role in space efficiency and safety by eliminating the vertical movement of the stem, which reduces the risk of accidents in crowded or confined industrial settings and allows for easier installation in tight spaces. This feature, combined with streamlined maintenance options, simplifies operational procedures, reducing labor and time requirements while enhancing overall workplace safety.

In addition to durability and safety, these valves deliver notable cost-effectiveness and energy savings through efficient flow control mechanisms that minimize pressure drops and optimize fluid management. Real-world applications across diverse industrial sectors—including power generation, mining, and manufacturing—demonstrate their versatility and performance benefits, such as improved process efficiency and reduced operational costs. By integrating advanced features like easy-to-access components and low-maintenance designs, OEM non-rising stem gate valves ensure smooth, reliable operation with minimal intervention. Overall, their combination of innovative materials, space-saving design, and economic advantages makes them a standout solution for industrial applications, driving productivity and sustainability while meeting the rigorous demands of modern infrastructure.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com